ROTARY TORQUE TRANSDUCER

OVERVIEW:

Using a highly-accurate non-contact technique, the series 425 (Strain gauge based) Rotary Torque Transducer and Torque Meter represent an ultimate torque sensor for anyone looking to measure torque, power, and speed with high accuracy and repeatability.

The typical application Market includes: Agriculture, Aerospace and Defense, Automotive, Civil Engineering, Green Renewable, Mining and Energy, Pumps, Valve, Motor, Engines, Test Rigs.

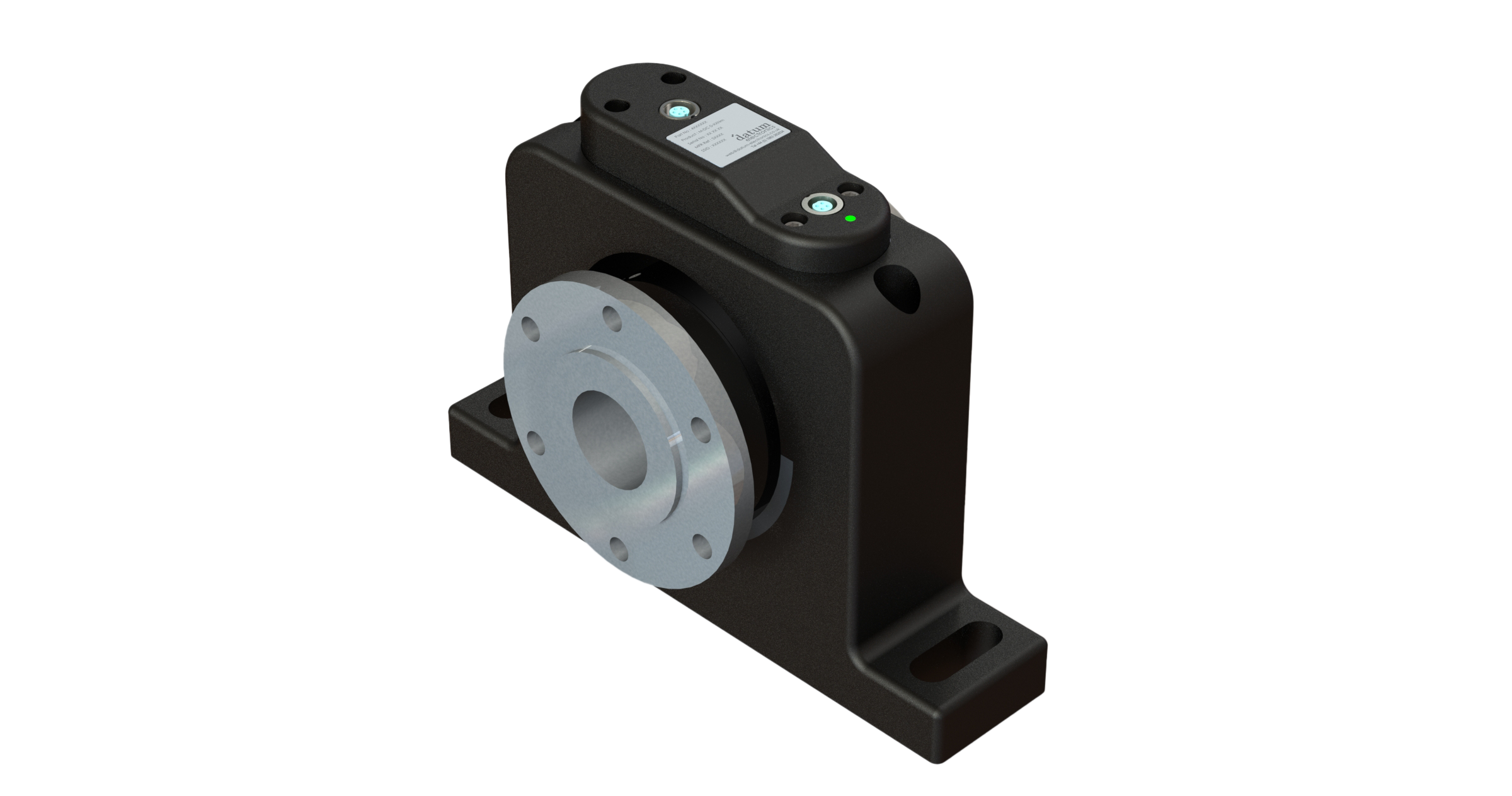

Datum Connect M425 Rotary Torque Sensor

- Torque Range: 0-10 to 60,000 Nm (Standard)

- Non-Linearity: 0.1%

- Repeatability: 0.05%

- Digital Sample Rate: 1 to 4000 samples per second(100 SPS as standard)

- Analog Sample Rates: 20 SPS as Standard

- Tranduser output Interfaces : Serial data via RS485, USB and Wifi 2.4 Ghz Transmition

- Analogue Outputs: 4-20mA configured 4-20mA (4-12-20mA): +/-10Vdc, +/-5Vdc, 0-10Vdc or 0-5Vdc at 20 samples per second (Via DCI)

- Operating Range: -10 to +70˚C

- Environmental Protection: IP54 (see high-speed RS425 Torque Sensor for IP67/68)

- Power Supply: 12-24Vdc via DCA

- Integreated RPM measurement

- Outputs: Torque, Speed, Power.

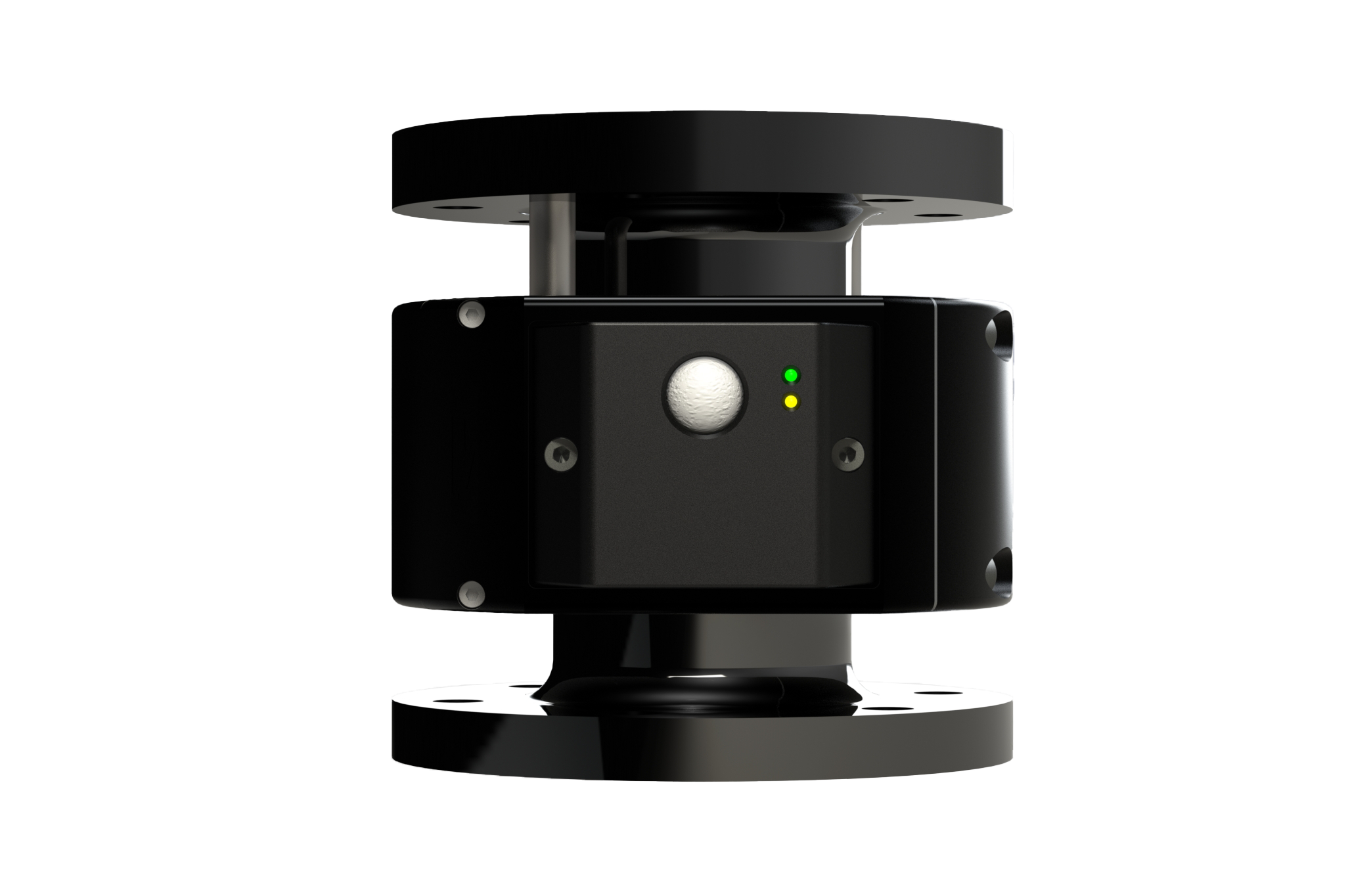

Datum Connect FF425 Non Contact Flange Torque Sensor

- Torque Range: 0-100 to 30,000 Nm (Standard)

- Non-Linearity: 0.1%

- Repeatability: 0.05%

- Digital Sample Rate: 1 to 4000 samples per second(100 SPS as standard)

- Analog Sample Rates: 20 SPS as Standard

- Tranduser output Interfaces : Serial data via RS485, USB and Wifi 2.4 Ghz Transmition

- Analogue Outputs: 4-20mA configured 4-20mA (4-12-20mA): +/-10Vdc, +/-5Vdc, 0-10Vdc or 0-5Vdc at 20 samples per second (Via DCI)

- Operating Range: -10 to +70˚C

- Environmental Protection: IP54 (Upgradeable to IP67/68 Please discuss with Sales)

- Power Supply: 12-24Vdc via DCA

- Integreated RPM measurement

- Outputs: Torque, Speed, Power.

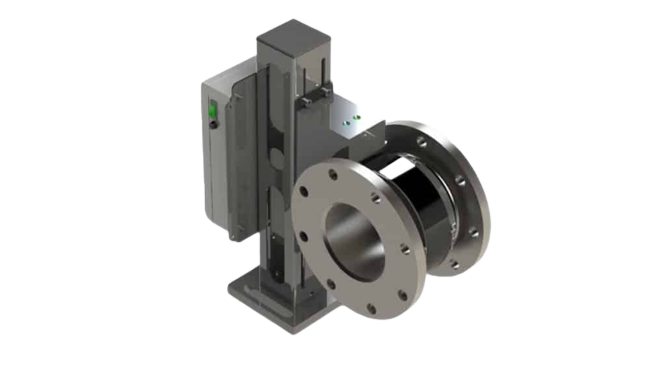

Datum Connect RS425 Contactless Torque Transducer

- Torque Range: 0-3 to 30,000 Nm (Standard)

- Non-Linearity: 0.1%

- Repeatability: 0.05%

- Digital Sample Rate: 1 to 4000 samples per second(100 SPS as standard)

- Analog Sample Rates: 20 SPS as Standard

- Tranduser output Interfaces : Serial data via RS485, USB and Wifi 2.4 Ghz Transmition

- Analogue Outputs: 4-20mA configured 4-20mA (4-12-20mA): +/-10Vdc, +/-5Vdc, 0-10Vdc or 0-5Vdc at 20 samples per second (Via DCI)

- Operating Range: -10 to +70˚C

- Environmental Protection: IP54 (see high-speed RS425 Torque Sensor for IP67/68)

- Power Supply: 12-24Vdc via DCA

- Integreated RPM measurement

- Outputs: Torque, Speed, Power.

- Ideal for High speed applications.

Datum Connect Tractor PTO Shaft Monitoring System

- Torque Ratings: 1,800 Nm (1 ⅜” shafts) and 2,500 Nm (1 ¾” shafts)

- Operating Speed: 540/1,000 RPM (Upto 3,000 RPM if Required)

- Spline Configuration: 1 ⅜” (6, 21 Splines) and 1 ¾” (6,20 Splines)

- Non-Linearity: 0.1%

- Repeatability: 0.05%

- Digital Sample Rate: 100 SPS as standard

- Analog Sample Rates: 20 SPS as Standard

- Tranduser output Interfaces : Serial data via RS485, USB and Wifi 2.4 Ghz Transmition

- Analogue Outputs: 4-20mA configured 4-20mA (4-12-20mA): +/-10Vdc, +/-5Vdc, 0-10Vdc or 0-5Vdc at 20 samples per second (Via DCI)

- Operating Range: -10 to +70˚C

- Environmental Protection: IP65

- Power Supply: 12-24Vdc via DCI

- Integreated RPM measurement

- Outputs: Torque, Speed, Power.

Auger Hawk C441 Helical Screw Pile Torque Sensor

- Outputs: Torque,RPM, Rotations, Highly accurate angle if insertion, Thrust, Insertion depth values, Pile geographical unique location through GPS technology through the Mobile/Tablet application

- Accurate – better than 1%

- Simple and Easy To use and Install

- Fast and Reliable Logging system

- Robust Design: IP67 Rated

- Rechargable Lifespan 3-4 weeks Usage

- Temperature range: -20 to +60°C

Custom Shaft Torque Sensor Solutions

We offer custom engineering solution by:

- Modifying or customising our standard products to fit into a customer’s requirements

- Developing new products from existing components and parts

- Adapting standard products to integrate into existing machinery or application

- Designing and manufacturing one-off design projects.

Datum Connect TDX Interface Kit

- The Datum Connect Interface has been designed to complement the following Datum Electronics range of Rotary (M425, RS425, FF425, PTO) Torque Sensors.

- Outputs Provided: USB Type B, RS485 Terminals Rx/Tx, 4 Configurable analogue outputs for Torque, Speed, Power.

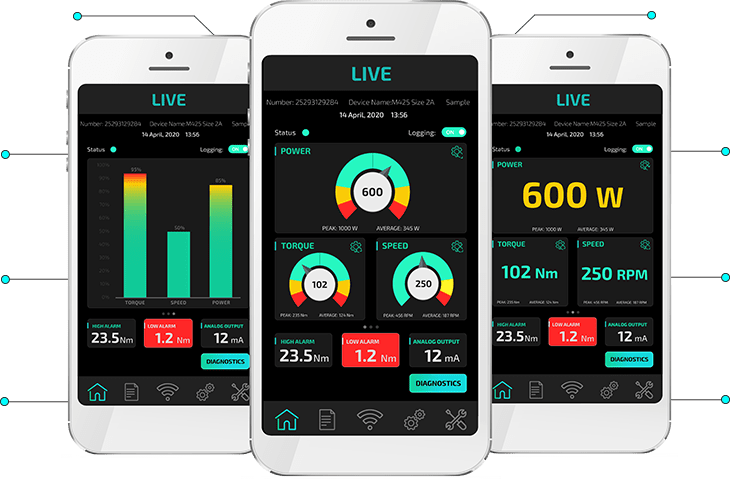

Datum Connect Application

- Datum Connect is the latest configuration and logging application, which supports the latest torque sensor technology. Datum Connect allows simple, quick and easy configuration of all Datum torque sensors, enabling users to see torque sensor outputs in real time in a format of their choosing.

- Compatible with Android, iOS and Windows versions.

- Features includes: Direct support to the product, permits live control of alarm settings, offers instantaneous logging of the data, as well as an email function, enabling future data analysis.