SHAFT POWER MEASUREMENT SOLUTIONS

OVERVIEW:

The Shaft Power Meter Systems are developed to provide real time and ongoing power monitoring data on propulsion shafts, thrusters and diesel generators. These devices are commonly used for fuel economy monitoring and equipment maintenance planning programs and can be used in conjunction with our EEXI | ShaPoLi solution to keep vessel owners in line with the latest legislation.

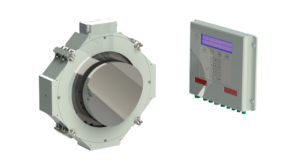

Marine Shaft Power Meter Systems

- Fully Modular System: Shafts from 150mm to 1,100mm (and above)

- 100% Contactless

- Maintenance Free

- Highly Reliable

- Instrumentation Accuracy: 0.1%

- System Accuracy: 0.1%

- System Repeatability: 0.05%

- Multiple Outputs: RS485, RS232, Modbus, Ethernet, 0-10V, 4-20mA, and USB Logging

- Operating Temperature: -15˚C + 80 ˚C

- Environmental Sealing: IP67

- Supply Voltage: 110 – 230 Vac, III or I, AC or DC 12-24V

- Can Be Installed and Commissioned in 1-2 days

- One-Time Calibration (No Re-Zero or Re-Calibration Required)

Shaft Power Measurement Kits

Standard Kit

- Shaft Sizes 90mm – 1100mm

- Battery Life 30-50 days operation

- Dual Channel Torque/Strain

- Thrust Option Available

- Shaft Speed Sensor

- PC Software

Compact Kit

- Shaft Sizes 30-500mm

- Battery Life 30 hours

- Single or Dual Channel

- Thrust Option Available

- Shaft Speed Sensor

- PC Software

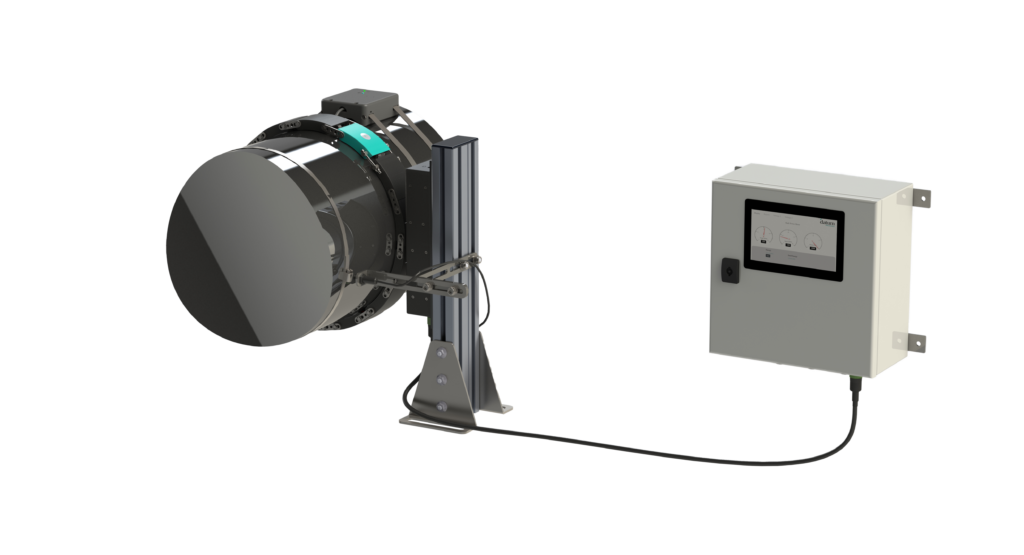

Naval Shaft Power Meter Systems

- The ship propeller shaft power meters have been through rigorous UK MOD and USA MIL testing programme for the harshest of environments, and are therefore verified in a number of marine conditions, including:

-

-

- MIL Spec std. 901-D shock

- 167-1A 2005 Vibration

- Safety Case to JSP430

- Shock to Def Stan 08-120

- EMC to Def Stan 59-41

- Selection of Marine Torsion meters Def Stan 02-606

- Magnetic Ranging to 08-123 DS31

-

-

- Measures Shaft Torque (kNm) Shaft Speed (rpm) Shaft Power (kW)

- Installed directly on ship shaft

- Non-Contact Transmission System

- Simple Robust Design

- Designed to fit variable size ship shafts

- Single or Dual Shaft Applications